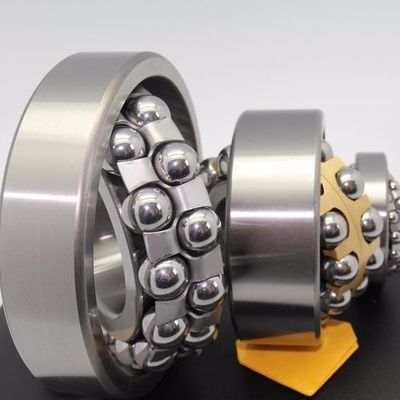

Pictures show

Drawing

Related models and specifications

| Bearing NO. |

Dimensions |

Weight |

|

Bearing NO. |

Dimensions |

Weight |

| Cylindrical bore |

Tapered bore (1:12) |

with adpter sleeve |

d |

d1 |

D |

B |

kg |

|

Cylindrical bore |

Tapered bore (1:12) |

with adpter sleeve |

d |

d1 |

D |

B |

kg |

| 108 |

|

|

8 |

|

22 |

7 |

0.0146 |

|

135 |

|

|

5 |

|

19 |

6 |

0.01 |

| 126 |

|

|

6 |

|

19 |

6 |

0.096 |

|

1300 |

1300K |

|

10 |

|

35 |

11 |

0.06 |

| 127 |

|

|

7 |

|

22 |

7 |

0.015 |

|

1301 |

1301K |

|

12 |

|

37 |

12 |

0.07 |

| 128 |

|

|

8 |

|

24 |

8 |

0.019 |

|

1302 |

1302K |

|

15 |

|

42 |

13 |

0.099 |

| 129 |

|

|

9 |

|

26 |

8 |

0.023 |

|

1303 |

1303K |

|

17 |

|

47 |

14 |

0.138 |

| 1200 |

1200K |

|

10 |

|

30 |

9 |

0.035 |

|

1304 |

1304K |

1304K+H304 |

20 |

17 |

52 |

15 |

0.174 |

| 1201 |

1201K |

|

12 |

|

32 |

10 |

0.042 |

|

1305 |

1305K |

1305K+H305 |

25 |

20 |

62 |

17 |

0.258 |

| 1202 |

1202K |

|

15 |

|

35 |

11 |

0.051 |

|

1306 |

1306K |

1306K+H306 |

30 |

25 |

72 |

19 |

0.39 |

| 1203 |

1203K |

|

17 |

|

40 |

12 |

0.076 |

|

1307 |

1307K |

1307K+H307 |

35 |

30 |

80 |

21 |

0.54 |

| 1204 |

1204K |

1204K+H204 |

20 |

17 |

47 |

14 |

0.119 |

|

1308 |

1308K |

1308K+H308 |

40 |

35 |

90 |

23 |

0.71 |

| 1205 |

1205K |

1205K+H205 |

25 |

20 |

52 |

15 |

0.114 |

|

1309 |

1309K |

1309K+H309 |

45 |

40 |

100 |

25 |

0.96 |

| 1206 |

1206K |

1206K+H206 |

30 |

25 |

62 |

16 |

0.226 |

|

1310 |

1310K |

1310K+H310 |

50 |

45 |

110 |

27 |

1.21 |

| 1207 |

1207K |

1207K+H207 |

35 |

30 |

72 |

17 |

0.318 |

|

1311 |

1311K |

1311K+H311 |

55 |

50 |

120 |

29 |

1.58 |

| 1208 |

1208K |

1208K+H208 |

40 |

35 |

80 |

18 |

0.418 |

|

1312 |

1312K |

1312K+H312 |

60 |

55 |

130 |

31 |

1.96 |

| 1209 |

1209K |

1209K+H209 |

45 |

40 |

85 |

19 |

0.469 |

|

1313 |

1313K |

1313K+H313 |

65 |

60 |

140 |

33 |

2.39 |

| 1210 |

1210K |

1210K+H210 |

50 |

45 |

90 |

20 |

0.545 |

|

1314 |

1314K |

|

70 |

|

150 |

35 |

2.98 |

| 1211 |

1211K |

1211K+H211 |

55 |

50 |

100 |

21 |

0.722 |

|

1315 |

1315K |

1315K+H315 |

75 |

65 |

160 |

37 |

3.55 |

| 1212 |

1212K |

1212K+H212 |

60 |

55 |

110 |

22 |

0.896 |

|

1316 |

1316K |

1316K+H316 |

80 |

70 |

170 |

39 |

4.19 |

| 1213 |

1213K |

1213K+H213 |

65 |

60 |

120 |

23 |

0.915 |

|

1317 |

1317K |

1317K+H317 |

85 |

75 |

180 |

41 |

4.95 |

| 1214 |

1214K |

|

70 |

|

125 |

24 |

1.29 |

|

1318 |

1318K |

1318K+H318 |

90 |

80 |

190 |

43 |

5.99 |

| 1215 |

1215K |

1215K+H215 |

75 |

65 |

130 |

25 |

1.35 |

|

1319 |

1319K |

1319K+H319 |

95 |

85 |

200 |

45 |

6.98 |

| 1216 |

1216K |

1216K+H216 |

80 |

70 |

140 |

26 |

1.65 |

|

1320 |

1320K |

1320K+H320 |

100 |

90 |

215 |

47 |

8.3 |

| 1217 |

1217K |

1217K+H217 |

85 |

75 |

150 |

28 |

2.1 |

|

1321 |

1321K |

|

105 |

|

225 |

49 |

9.55 |

| 1218 |

1218K |

1218K+H218 |

90 |

80 |

160 |

30 |

2.51 |

|

1322 |

1322K |

1322K+H322 |

110 |

100 |

240 |

50 |

11.8 |

| 1219 |

1219K |

1219K+H219 |

95 |

85 |

170 |

32 |

3.06 |

|

|

|

|

|

|

|

|

|

| 1220 |

1220K |

1220K+H220 |

100 |

90 |

180 |

34 |

3.68 |

|

2300 |

|

|

10 |

|

35 |

17 |

0.085 |

| 1221 |

1221K |

|

105 |

|

190 |

36 |

4.4 |

|

2301 |

|

|

12 |

|

37 |

17 |

0.095 |

| 1222 |

1222K |

1222K+H222 |

110 |

100 |

200 |

38 |

5.2 |

|

2302 |

|

|

15 |

|

42 |

17 |

0.114 |

| 1224 |

|

|

120 |

|

215 |

42 |

|

|

2303 |

|

|

17 |

|

47 |

19 |

0.158 |

| 1226 |

|

|

130 |

|

230 |

46 |

|

|

2304 |

2304K |

2304K+H2304 |

20 |

17 |

52 |

21 |

0.219 |

| 1228 |

|

|

140 |

|

250 |

50 |

11 |

|

2305 |

2305K |

2305K+H2305 |

25 |

20 |

62 |

24 |

0.355 |

| |

|

|

|

|

|

|

|

|

2306 |

2306K |

2306K+H2306 |

30 |

25 |

72 |

27 |

0.501 |

| 2200 |

2200K |

|

10 |

|

30 |

14 |

0.047 |

|

2307 |

2307K |

2307K+H2307 |

35 |

30 |

80 |

31 |

0.675 |

Description

1)Spherical Self-Aligning Ball Bearing has two kinds of structure:cylindrical or tapered hole, the cage

material is steel plate, brass,etc.. Its characteristics is spherical raceway, with the natureof mind, can

automatically adjustable to compensate concentration and shaft deflection caused by error, but theinner

and outer rings relative inclination shall not be more than 3 degrees.

2)Spherical Self-Aligning Ball Bearing can bear larger radial load,but also can withstand axial load. This

kind of bearing outer ring raceway is spherical shape, so it is self-aligning performance,when the axial

force bending or tilt the inner center line and center of the outer ring line relative slope up to a maximum

of 1 to 2.5 degrees bearing can still work.

3)Taper bore of 1:1 2 or 1:30. In order to strengthen the lubrication performance of the bearing, the bearing

outer ring of the oil groove and the processing of three oil hole.

4)Spherical Self-Aligning Ball Bearing is applied to withstand heavy load and impact load, precision

instruments, low noise motor, automobile,motorcycle, metallurgy, rolling mill, mine, oil, paper, cement,

sugar industry,general machinery and so on.

Detailed Specification

1.The components of the self aligning ball bearings include two rows of balls, the cage, the inner ring,

and the outer ring with a common concave sphered raceway

2.The material of the bearings is the high quality bearing steel CGr15

3.Particularly suitable for applications where considerable shaft deflections or misalignment are to be

expected

4.produces self-aligning ball bearings to several designs. These are

– open bearings of the basic design

– sealed bearings

– open bearings with an extended inner ring

– self-aligning ball bearing are constructed with the inner ring and ball assembly contained within an outer ring that has a spherical raceway .This construction allows the bearing to tolerate a small angular misalignment

resulting from deflection or improper mounting

5.Suffix meaning

M:Machined brass cage, ball centred; different designs and material grades are identified by a figure following

the M, e.g. M2

TN9:Injection moulded snap-type cage of glass fibre reinforced polyamide 66, ball centred

C3 :Radial internal clearance greater than Normal

E :Optimized internal design

K :Tapered bore, taper 1:12

2RS1 :Sheet steel reinforced contact seal of acrylonitrile-butadiene rubber on both sides of the bearing

TN :Injection moulded snap-type cage of polyamide 66, ball centred

VE294 :Annular groove and six lubrication holes in the inner ring

Bearing Features

•The lowest friction

•Quiet and smooth operation at high speed

•Spherical raceways to minimise noise

•Self-aligning and insenitive to angular misalignments of the shaft relative to the housing

•Widespread use and versatility

22318E Bearing data sheet for your reference:

spherical ball bearing series--double row 1200 series, 1300 series, 2200 series, 2300 series

Spherical roller bearing series

---Single row series: 21300 series

---Double row series: 22200 series, 22300 series,23000 series, 23100 series, 23200 series, 23300 series,

23900 series, 24000 series, 24100 series,

Characteristics

High temperature capacity

Available cages: Pressed steel cage, machined brass cage

Application

Stand heavy load and the applicable to impact load, precision instruments, low noise machine, automobile,

motorcycle, metallurgy, rolling mill, mine, petroleum, paper making, cement, the sugar industry, the

general machinery, etc,

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!